Click on the tab for more information:

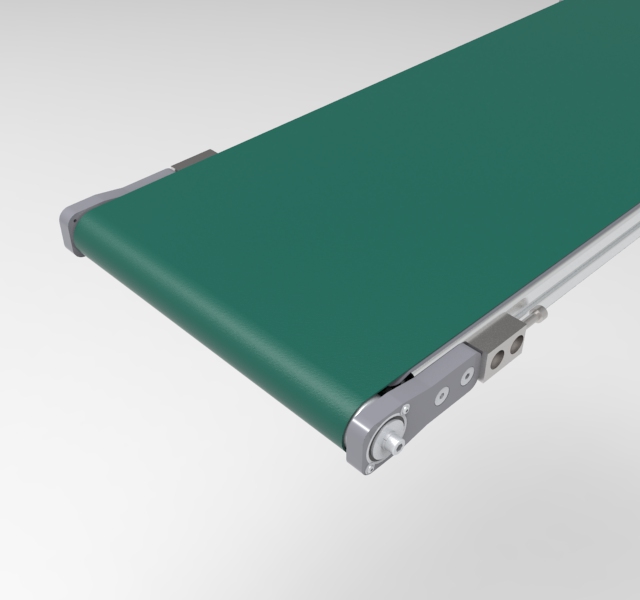

- the most widespread type of conveyor, which is characterized by its variability from a conveyor for small material or workpieces, plastic parts in molding shops or assembled assemblies from production lines to a mining conveyor intended for exterior use.

- economically advantageous solution

- a wide portfolio of belt types according to the type of transported material

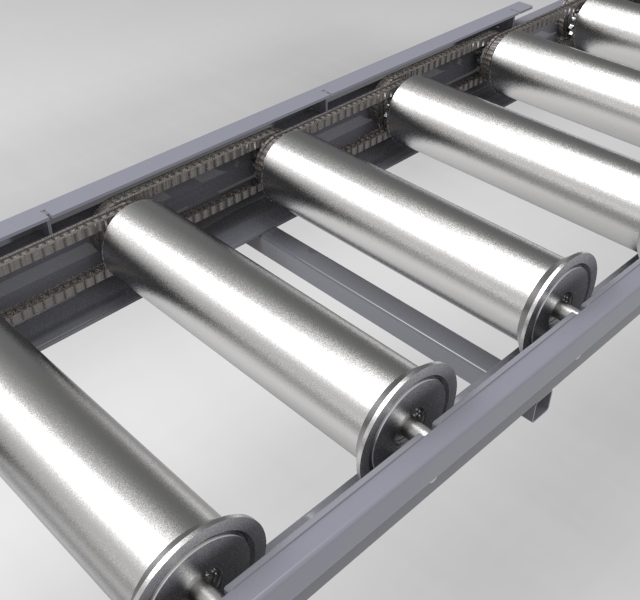

- roller conveyor can be both powered and drop track

- roller conveyors stand out due to their capacity and the possibility of easy accumulation of parts and thereby ensuring continuous regular supplies of material to production or efficient storage of parts as stock before further processing.

- wide possibilities of use from gravity tracks to powered tracks with a large load range

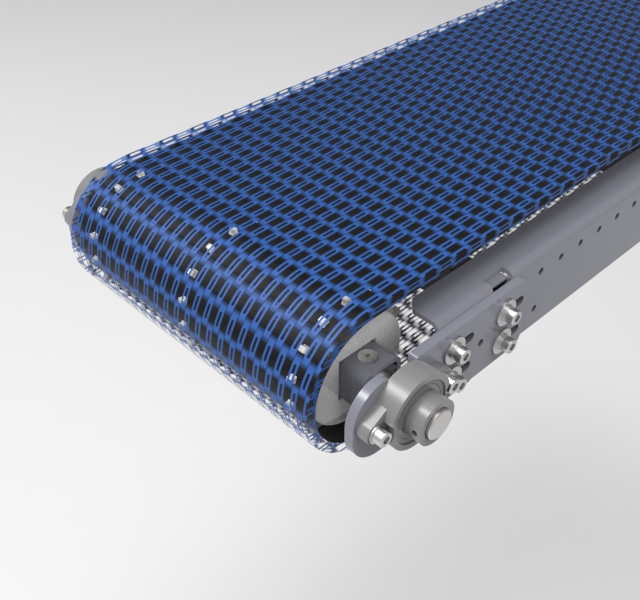

- conveyors with a modular belt are very often used in the food industry, paint shops or warehouses

- the perforation of the belt ensures that any dirt does not come into contact with the transported parts, but easily falls through

- another of the benefits of modular belts is their harmlessness to health, therefore they are also suitable for use in direct contact with food

- type of belt conveyor with wide variability - belts can be equipped with various conveyor elements such as e.g. gates

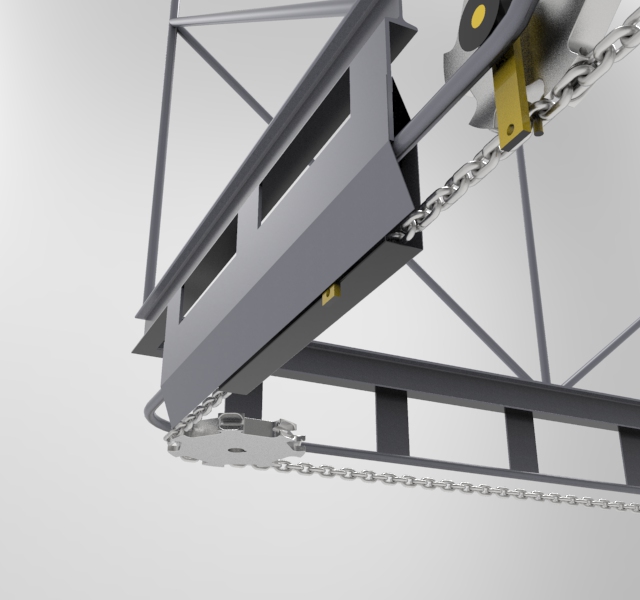

- saves space or floor space for use by other technologies

- suitable for the transport of non-standard parts and assemblies

- suitable for continuous operation / one piece flow

- economical solution for large parts

- the possibility of using a wide portfolio of belt types according to the type of transported material

- ergonomically suitable solution for large parts without the need to lean forward (the operator can step between the bars) and reduces the physical burden on workers

Conveyors for production lines and warehouses

Conveyors are an indispensable element in production lines and warehouses, where it is necessary to efficiently and reliably transport divided or piece material. There are several types of conveyors that are designed specifically for these purposes, including roller, belt, and overhead conveyors. Each type has its specific advantages and disadvantages, which is why it is important to choose the right type of conveyor for a specific application.

When choosing a suitable conveyor, you need to take into account:

- Purpose of use – for example, a belt conveyor as an intermediate warehouse

- Size and weight of pieces on the conveyor - chain or roller conveyors for large sizes

- The temperature of the parts coming into contact with the conveyor belt - for parts with high temperature conveyors chain, roller or link conveyors

- Humidity, temperature and dustiness of the environment - stainless steel conveyors for demanding environments

- Type of industry and legislative requirements - stainless steel conveyors or modular belt conveyors for the food industry

- Rigidity of the pieces themselves - for malleable pieces by belt conveyors

- Convenient access and available space - for a small occupied area, suspended or spiral conveyors

- Roller conveyors used as drop conveyors are suitable for the use of fall or the need for accumulation

Roller conveyors

Roller conveyors are ideal for transporting pieces with smaller weights and dimensions. They are equipped with rollers placed at regular intervals, which allow smooth movement of the material along the entire length of the conveyor. These conveyors are suitable for environments where quick and easy material handling is needed, such as an inter-operational warehouse.

Belt conveyors

Belt conveyors are more powerful and suitable for transporting larger and heavier pieces of material. They are equipped with belts that smoothly transfer the material along the entire length of the conveyor. Belt conveyors are often used in industries where it is necessary to handle malleable pieces of material. They are durable and reliable, which is important for demanding operating conditions.

Suspended conveyors

Overhead conveyors are suitable for environments with limited space and a small footprint. These conveyors are suspended from the ceiling and the material is transported in the air. They are ideal for handling pieces of material that require access from below or have specific transport requirements.

When choosing a suitable conveyor, it is important to consider several factors, such as the size and weight of the transported pieces, ambient temperature, humidity, dustiness, type of industry and available space. It is also important to pay attention to the fulfillment of legislative requirements in the given sector.

Our company, Machine Conveyor, offers a wide range of conveyors, including roller, belt and overhead conveyors, designed for different applications and needs. We specialize in the supply, installation and maintenance of conveyors that meet the highest standards of quality and reliability.