Click on the tab for more information:

- the articulated conveyor can be used for demanding and heavy operations with high abrasion resistance

- also available in stainless steel belt design - conveyors in stainless steel design are an ideal solution for the food industry

- high resistance and easy maintenance

- wide dimensional variability

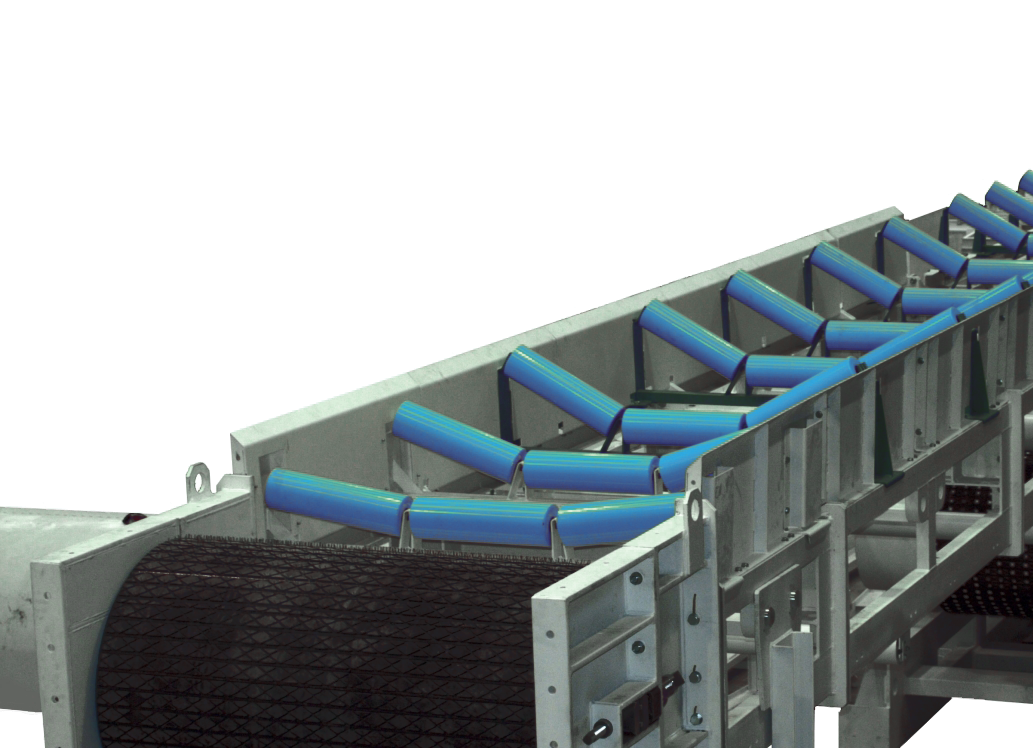

- belt conveyors designed for bulk materials are characterized by large transport volumes and speeds

- intended only for horizontal transport or slight inclines

- a wide portfolio of belt types according to the type of transported material

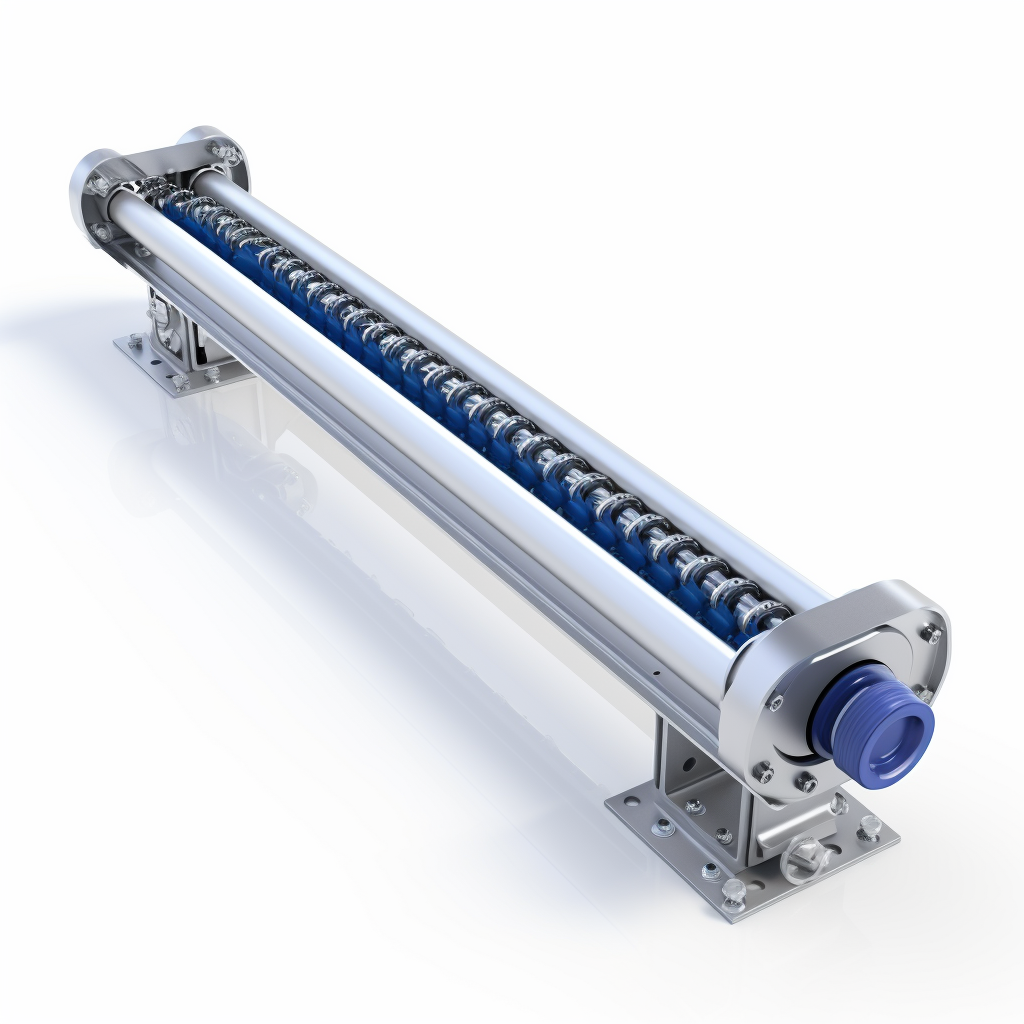

- screw conveyors are suitable for loose materials with a large angle of inclination of the conveyor track

- for conveying material in a horizontal direction or at an inclination of up to 60°

- suitable for use in transporting dusty materials

- also suitable for transporting slurries

- for conveying material in a horizontal direction or at an inclination of up to 30°

- suitable for use in transporting dusty materials

- also suitable for transporting slurries

In today's industrial environment, the transportation of bulk materials is an essential part of many production processes. Bulk material conveyors are one of the most efficient and widely used devices for transferring, transporting and handling these materials. They are designed to ensure a smooth and trouble-free flow of bulk materials, whether they are grains, powders, granules or other types of materials.

Conveyors for bulk materials

They offer a number of advantages that make production processes easier and more efficient. One of the main advantages is their ability to transport materials over distances ranging from a few meters to several kilometers, which allows easy transport of bulk materials on a large scale. In addition, they are equipped with different types of conveyor belts, chains or screws, which are adapted to the specific needs and characteristics of bulk materials.

Another advantage of bulk material conveyors is their ability to regulate the speed and flow of the material, which allows precise control over the transportation process. This minimizes the risk of overflow or blockage and ensures a stable and smooth flow of material throughout operation.

Bulk material conveyors are also designed with ease of maintenance and cleanliness in mind. They are equipped with systems for removing dirt and excess material, which minimizes the risk of pollution and ensures optimal conditions for operation. Regular maintenance and inspection is important to maintain optimal performance and extend the life of conveyors.

Our company Machine Conveyor specializes in the supply and installation of bulk material conveyors. Our wide range includes different types of conveyors, including conveyor belts, screw conveyors, chain conveyors and more. Our devices are of high quality, reliable and adapted to the needs of our customers.

If you need an efficient and reliable solution for transporting and handling bulk materials, contact us. We are ready to assist you with the selection, installation and maintenance of bulk material conveyors to achieve optimum performance and increase the productivity of your production process.

Several factors are important to consider when choosing bulk material conveyors. One of the main factors is capacity, i.e. how much material the conveyor can transport per unit of time. This is dependent on the speed of the conveyor belt or screw and the size of the material being transported.

Another factor is the maximum length and height of the transmission path. It is important to consider how far and how high the material needs to be transported. This factor depends on the specific requirements of your production line.

Bulk material conveyors also offer various options for regulating and controlling the flow of material. This includes an adjustable belt or screw speed that allows material transfer to be tailored to specific process requirements.

Modern bulk material conveyors often use artificial intelligence and sensor technology to monitor condition and optimize operations. This technology enables accurate evaluation of conveyor performance, fault detection and maintenance prediction.

Conveyors for bulk materials are an integral part of modern production processes. Their correct selection and correct setting can significantly increase the efficiency and productivity of your production line. If you are looking for a reliable bulk material conveyor supplier, we are here for you. Contact us and we will be happy to provide you with more information and help you choose the solution that best suits your needs.