Belt conveyor

Probably the most widespread type of conveyor, which is characterized by its variability from a conveyor for steel extrusions or workpieces, plastic parts in molding shops or assembled assemblies from production lines to a mining conveyor intended for exterior use. More theory here.

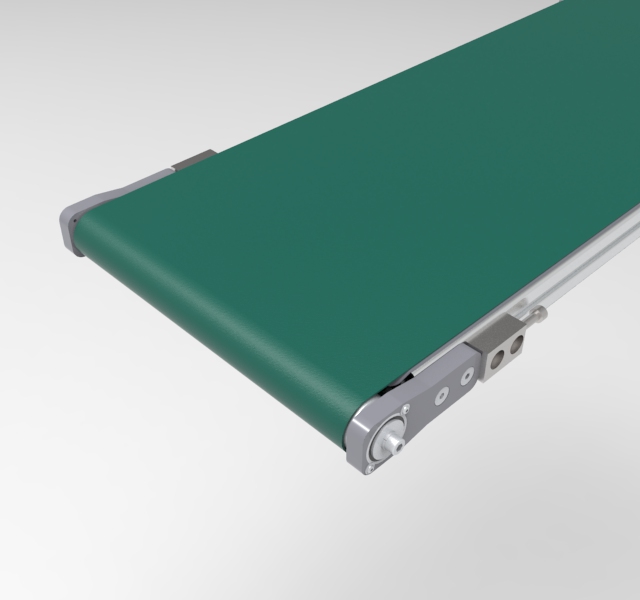

Belt conveyor for warehouses and industrial production

At Machine Conveyor, we offer innovative belt conveyors for warehousing and industrial production that address the key needs of your business, such as material distribution, inter-operation bins and varying speeds and heights. Our solutions help you increase efficiency, reduce costs and improve the safety of your workplace.

- Precise material distribution: Our belt conveyors are equipped with intelligent branches and other functions that allow easy and accurate distribution of materials according to codes or product type, which increases productivity and minimizes errors.

- Inter-Operation Bins: Our conveyor systems allow for the creation of inter-operation bins, which helps to balance out different takts and downtime in the production process, increasing overall efficiency.

- Flexible speeds, fences and heights: Our belt conveyors are designed to meet safety requirements while offering a variety of speeds, fences and heights. Thanks to ergonomic solutions, operators can easily perform visual inspections without the risk of safety incidents.

Our belt conveyors for storage and industrial production are the ideal solution for your business, easily adapted to your specific needs.

Belt conveyor for production

Belt conveyors are also used in production because of the integral impermeable surface and the ability to hold the material over the entire surface. It is therefore suitable for the transport of malleable material or the need to move material without breaking or bending.

Conveyors can be shaped and adapted to any application, from the smallest and smallest parts to large and rough pieces with sharp edges, including various motor positions (end drive, center drive, drive in the drive cylinder - drum or with chain transmission).

Conveyors for packaging machines

Conveyor belts can be equipped with gates or bellows to prevent overflow of material. Such a conveyor belt is capable of an inclination of 45° and is therefore capable of a large elevation over short distances. Conveyor belts can be applied from different materials for a wide range of applications. These are one of the reasons why belt conveyors are suitable for dosing packages and other food machinery. A hopper is used as the simplest dosing mechanism. The hopper is equipped with material flow regulation - automatic or manual.

Hopper with manual operation

It is suitable for continuous dosing, where the operator adjusts the material flow and frequent stops cannot occur.

Automatic dosing conveyors

Automatic conveyors are able to monitor the level in the packaging machine and dose the exact amount accordingly so that the packaging machine is not overcrowded. Depending on the state of the level, it also closes the dosing from the hopper. It is a more expensive version of conveyors, but at the same time a solution for frequently stopped operations or operations with fluctuating traffic.

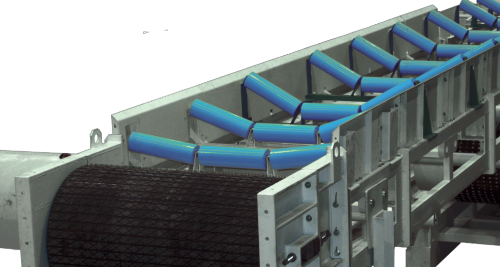

Conveyors for the construction industry

One of the advantages of the belt is the possibility of a damping effect to eliminate noise in operations and, of course, the price. You can choose from a number of belt types, so that the life of the belt is as long as possible and the conveyor does not need frequent maintenance. They are used for very fine materials up to coarse materials such as gravel. With such a conveyor, the belt is formed into a trough.

One of the advantages of the belt is the possibility of a damping effect to eliminate noise in operations and, of course, the price. You can choose from a number of belt types, so that the life of the belt is as long as possible and the conveyor does not need frequent maintenance. They are used for very fine materials up to coarse materials such as gravel. With such a conveyor, the belt is formed into a trough.

Conveyors for the plastics industry

Our conveyors are the ideal solution for transporting plastic moldings, granules and finished products in manufacturing plants and assembly lines.

Our conveyors for the plastics industry offer the following advantages:

- Reliability and long life: Our conveyors are made of quality materials and designed to withstand harsh production conditions, ensuring reliability and long life.

- Flexible solutions: We offer a wide range of conveyors that can be adapted to different production needs, allowing you to find the ideal solution for your plastics plant.

- Ease of maintenance and cleaning: Our conveyors are designed with ease of maintenance and cleaning in mind, ensuring that your production lines are always in optimal condition.

- Safety and ergonomics: Our conveyors for the plastics industry are designed with safety and ergonomics in mind, ensuring a comfortable and safe working environment for your employees.

- Energy efficiency: Our conveyors are designed for low energy consumption and to minimize operating costs, allowing you to save on costs and reduce your impact on the environment.