Advantages and features of the roller conveyor

Economical, ecological and safe operation of roller conveyors:

Economical, ecological and safe operation of roller conveyors:

Unlike traditional belts, the roller conveyor reduces friction between the surface and the box, which increases the life of the boxes and minimizes the risk of damage. At the same time, they also reduce the consumption of electrical energy for the transport of goods, because they do not catch up with the friction between the belt and the supporting structure.

Flexibility of roller tracks:

Roller conveyors can be easily adapted to different box shapes and sizes.

Roller Conveyor Maintenance and Safety:

Roller conveyors are designed to require minimal maintenance. Due to their simplicity, they are less prone to failure than more complex transport systems. In addition, the movement of cardboard boxes along the roller conveyor is safe, as the risk of jamming or wedging is minimized.

Production of roller conveyors

Roller conveyors stand out due to their capacity and the possibility of easy accumulation of parts and thereby ensuring continuous regular supplies of material to production or efficient storage of parts as stock before further processing. More theory here.

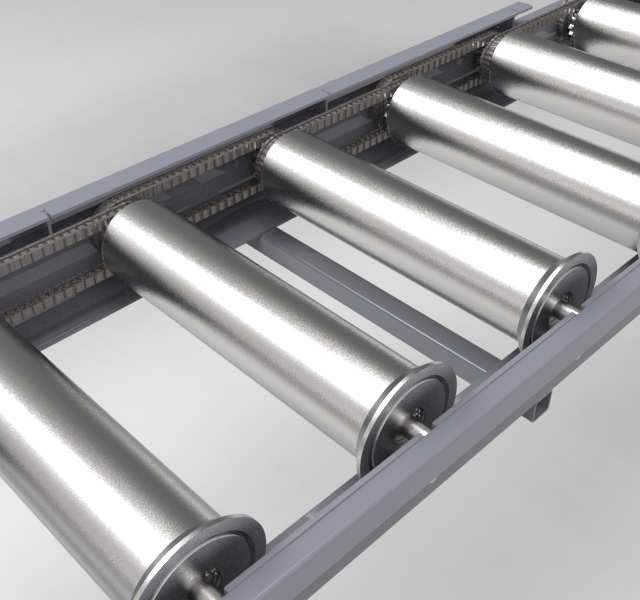

The roller conveyor consists of a series of rollers placed parallel to each other, which enable easy movement of goods along their surface. The movement can be either gravitational, when the boxes move by their own weight on a slight slope, or the roller conveyor can be driven by a motor, i.e. the roller conveyor is designed as a powered or as a drop path, depending on the need.

Conveyor for cartons

The roller conveyor is the ideal solution for handling cardboard boxes in warehouses and production areas. Its design and functionality offer efficiency, security and reduced maintenance costs, making this system an ideal choice for modern businesses looking to optimize their operations.

Conveyors for pallets

Roller conveyors are generally suitable for packaging systems. Wooden or plastic pallets do not require rollers and are easy to move over. The rollers of the roller conveyor have an advantage in carrying capacity - the cylinders can be dimensioned for almost any carrying capacity. If the cylinders are deformed after time - out of round, the cylinders were obviously undersized. We can manufacture cylinders directly for any application.

Conveyors for gitter boxes

Roller conveyors can also be used for gitterboxes, but only on the condition that the gitterbox has long enough crawlers to pass between each one. Chain conveyors are suitable in the event that the piles are shorter.

Drop paths

By tilting the track, we can use gravity for propulsion. It is a maintenance-free system that can be used anywhere and for any reason. There is only one issue and that is safety when handling heavy objects. A heavy load can be very dangerous on a drop path and therefore it is necessary to use retarders or brakes. Also stopping heavy loads can be problematic with regard to mutual damage - our company has a lot of experience using such elements.

Mobile conveyor tracks

With regard to the possibility of the drop path function, the roller conveyor in the mobile version is a very simple and efficient matter to operate.

Sheet metal conveyor

The sheet metal conveyor is a specific matter. On the one hand, it is convenient to use belt conveyors , but they are very susceptible to damage from the sharp edges of the belt. Roller conveyors can be used for this purpose, they will be extremely durable, on the other hand, a large number of rollers is required. Another option is to use chain conveyors, but they can scratch the sheet. It therefore depends on the exact requirements and properties of the transported material.

Accumulation conveyors

With the roller conveyor, it is possible to drive almost every roller separately and to combine it with the drop function. It is the most suitable choice for material accumulation, or the best performance/price ratio.

Conveyor arches

Complete sets of roller conveyors including arches can be supplied to ensure a continuous production process. We supply the conveyor bends (bends) produced by us as standard in a 90° design. It is a non-guiding roller track (i.e. without a drive) with a base structure with an adjustable height of 900 - 1400 mm and a standard installation size of 1200 x 1200 mm. The maximum load capacity of this conveyor bend is 50 kg.

Price from CZK 19,900 without VAT

We can make the track for you in the following design:

with straight cylinders - i.e. the material on the conveyor does not rotate in the direction of the track

with conical cylinders - i.e. the material turns itself in the direction of the path

Additional possible options:

braked variant "standard" - 3 braked standard rollers on the conveyor

braked variant "cone" - 3 braked cone rollers on the conveyor

Other designs on request.

Production of conical cylinders

Cone conveyor rollers are suitable for guiding the material along the conveyor without rotating the material itself. They are also suitable for materials with a temperature higher than 60°C.

We manufacture steel cone rollers for conveyor bends from a diameter of 50 mm. Cylinders are produced by rolling sheet metal. We are able to produce dimensions up to 2 m long.

Standard cylinders have a turning radius of 2m (outer radius), the length of the cylinders is according to the customer's request.

The cylinders are driven by circular belts with a diameter of 6 mm, the cylinders are terminated with a hole for an M8 screw.

Other dimensions or mounting on request.